Aluminum Curtain Walls: Innovators of Architectural Aesthetics and Practitioners of a Green Future

Publish Time: 2025-09-08

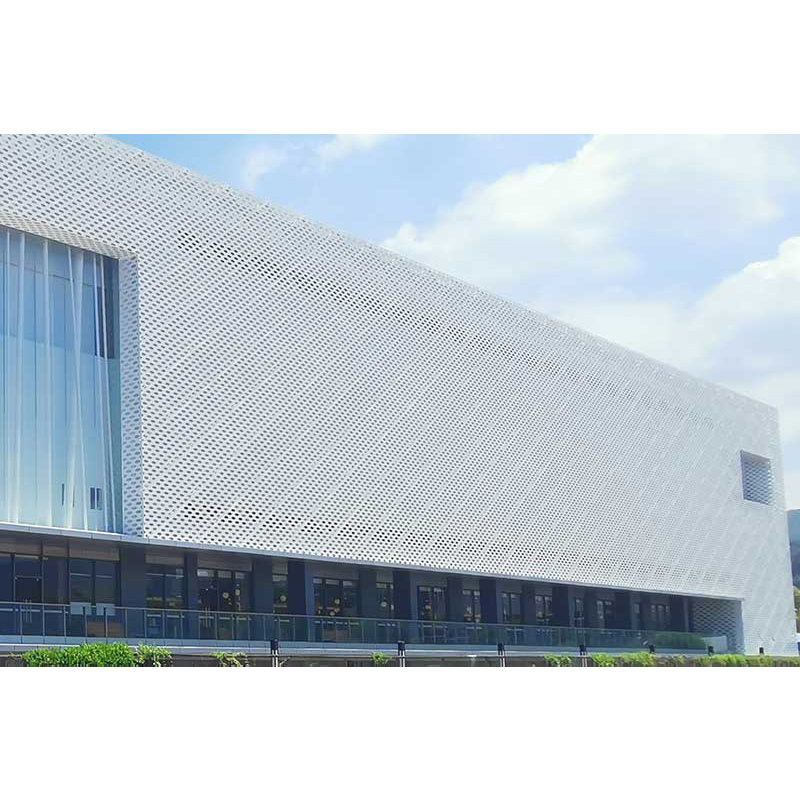

Driven by the dual trends of urbanization and green building concepts, aluminum curtain walls are radically reshaping the design logic and functional boundaries of building facades. From super-high-rise office buildings to cultural and arts centers, from high-end residences to smart city landmarks, aluminum curtain walls, with their lightweight structure, ultimate aesthetic expression, and lifecycle sustainability, have become an indispensable "metal cladding" for modern architecture.I. Structural Revolution: The Perfect Balance of Lightweight and High StrengthThe core advantage of aluminum curtain walls lies in the deep integration of their material properties and structural design. Aluminum has a density only one-third that of steel, but through alloying and precision machining, a 3.0mm thick aluminum veneer can achieve a tensile strength of 100-280N/mm². In super-high-rise buildings, it can replace some stone curtain walls, reducing the overall building load by over 20%. For example, the adoption of aluminum veneer curtain walls in a Shanghai high-rise office building reduced infrastructure costs by 15%. The modular design of the open curtain wall system also allows for rapid installation and removal of panels, leaving room for functional upgrades.The extrusion and bending processes of aluminum profiles offer endless possibilities for curtain wall framing. The concealed frame system composed of vertical columns and transverse beams, combined with the precise connection of aluminum angles and reinforcing ribs, creates a structural system with exceptional resistance to wind pressure and deformation. In typhoon-prone coastal areas, the aluminum curtain wall withstands winds exceeding force 12. Its four-corner welds and fluorocarbon coating effectively resist salt spray erosion, resulting in a service life exceeding 25 years.II. Aesthetic Subversion: From Flat to Three-Dimensional Form LiberationThe plastic revolution of aluminum curtain walls is breaking the two-dimensional limitations of traditional building facades. Through CNC bending and 3D printing technologies, aluminum veneer panels can be fabricated into complex geometric forms such as hyperbolic surfaces, rhombuses, and wavy shapes, even achieving artistic textures like "ice cracks" and "water sleeves." The Guangzhou Opera House's exterior walls feature specially treated aluminum panels that mimic the crackle of bronze artifacts, transforming the building into a cultural symbol of the city. A cultural and arts center in Suzhou features a hyperbolic aluminum curtain wall that evokes the vibrant atmosphere of the Jiangnan waterside villages. Its smooth curves create a contrast between the real and the imaginary with the glass curtain wall, creating a dynamic play of light and shadow.The innovations in color and texture are equally astonishing. Anodizing imparts metallic lusters like bronze and champagne gold to the aluminum curtain wall, while fluorocarbon spraying technology allows for the creation of thousands of colors to meet personalized needs. In a coastal building in Hainan, the fluorocarbon-treated aluminum curtain wall maintains its color saturation after 10 years of salt spray erosion. Its self-cleaning coating uses nanotechnology to decompose organic pollutants, reducing cleaning frequency by 80%.III. Green Gene: A Sustainable Closed Loop from Materials to SystemsThe environmental value of aluminum curtain walls extends throughout their entire life cycle. As a 100% recyclable material, the recycling process of aluminum veneer panels consumes only 5% of the energy required to produce primary aluminum. In urban renewal projects, aluminum curtain walls from old buildings can be processed and reprocessed into new panels or other aluminum products, creating a closed-loop resource loop. A Shenzhen factory renovation project recycled the original aluminum curtain walls, reducing construction waste while also lowering energy consumption for new material production by 30%.In the energy-saving field, the integrated use of aluminum curtain walls and photovoltaic panels (BIPV) is becoming a trend. A commercial complex in Chongqing uses a curtain wall system combining perforated aluminum panels with thin-film photovoltaics, enabling the building to generate its own electricity and reducing carbon dioxide emissions by 1,200 tons annually. Furthermore, the sound insulation layer installed inside the aluminum panels reduces energy consumption by 30%, meeting the mandatory 70% green building material ratio required by the Green Building Evaluation Standards.IV. Technological Frontiers: The Future of Intelligence and CustomizationWith the widespread adoption of 5G and the Industrial Internet, aluminum curtain wall production is entering an era of intelligent customization. BIM technology limits design error rates to less than 0.5%, while CNC bending equipment enables mass production of complex shapes, shortening delivery times by 15 days. On the construction side, the dry-hanging system, secured with keels and angle brackets, shortens construction times by 30% compared to traditional wet-hanging systems, making it particularly suitable for large-scale infrastructure projects such as airports and high-speed rail stations.In the future, aluminum curtain walls will deeply integrate IoT and AI technologies. Smart dimming aluminum panels use optoelectronic materials to adjust light transmittance, reducing air conditioning energy consumption by 20%. Acoustic perforated aluminum panels (aperture size 0.5-5mm) absorb mid- and high-frequency noise, improving indoor comfort. Aluminum curtain walls integrated with AR technology can even achieve dynamic light and shadow projection, transforming building facades into urban public art.V. Market Trends: Driven by Dual High-End Development and GlobalizationAccording to industry data, the Chinese aluminum curtain wall market exceeded 45 billion yuan in 2025 and is expected to reach 92 billion yuan by 2030, accounting for over 50% of the global market. In the high-end residential sector, the proportion of aluminum facades has jumped from 15% in 2020 to 40% in 2025. Projects like New York's ONE57 and Shanghai's Tomson Yipin are defining the standard of luxury living through their "aluminum + glass" combination. In commercial buildings, composite aluminum panels (such as nano-self-cleaning aluminum panels and ventilated perforated aluminum panels) meet the requirements of ventilation, sound insulation, and dynamic light and shadow, becoming the material of choice for landmark buildings.Regional markets include the Yangtze River Delta, the Guangdong-Hong Kong-Macao Greater Bay Area, and the Chengdu-Chongqing Economic Circle, which account for 63% of the market share. Urban renewal projects in cities like Shanghai and Hangzhou are driving annual growth in aluminum panel demand of 12%. Aluminum curtain walls account for over 70% of super-high-rise buildings in Shenzhen and Guangzhou. Demand in central and western cities is growing at an 8-10% rate, exceeding the national average, driven by increased infrastructure investment.The beauty of metal, outlining the future of citiesThe evolution of aluminum curtain walls is a story of innovation at the intersection of materials science and architectural art. From structural load reduction to aesthetic enhancement, from performance-focused design to green recycling, aluminum curtain walls are redefining the boundaries of modern architecture, using technology as a guide and sustainability as a tool. With the advancement of the "dual carbon" goals and the construction of smart cities, aluminum curtain walls will undoubtedly carry more functions and imagination, becoming a key link connecting human living ideals with the future of the Earth's ecology.